Absolutely! The JADE-450SH stands out as a powerhouse in the JADE series, catering to diverse flooring needs with its advanced features. Its 3kW motor provides the strength required for demanding tasks, while the Dual Drive Technology ensures unparalleled precision and flexibility, enabling professionals to achieve exceptional results.

The machine's cost-efficient design and robust build make it a long-term investment, capable of withstanding harsh conditions while maintaining low maintenance requirements. Furthermore, its operator-friendly attributes, such as the adjustable handle, intuitive control panel, and efficient tool-changing system, streamline the workflow, saving time and energy. Whether tackling expansive surfaces or intricate corners, the JADE-450SH rises to the occasion, proving itself as a reliable and versatile solution for flooring professionals.

![Floor Grinding Machine For Sale Floor Grinding Machine For Sale]()

PARAMETER

| Motor Power | 3kW |

| Rated Voltage/frequency | AC220V/50Hz/60Hz |

| Rated Current | 12.5A/11.7A |

| Inverter Power | 4kW |

| Working Width | 450mm |

| Weight | 154kg |

| Grinding Pressure Weight | 120kg |

| Transmission Method | Synchronous Belt |

| Gearbox Type | / |

| Damping Form | Rubber Damping |

| Grinding Disc Type | Round |

| Grinding Disc | 155mm |

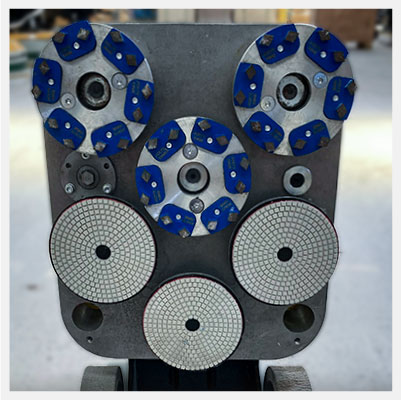

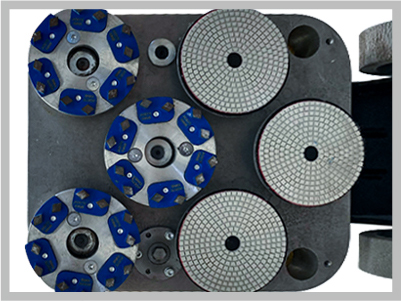

| Number Of Grinding Wheels | 6 |

| Number Of Abrasive Discs | 2*6pcs |

| Grinding Motor Speed | 300~1800r/min |

| Travel Drive | Hand push |

| Work Efficiency (Max) | 300㎡/h |

| Power Supply Wiring | 4mm² |

| Body Dimensions | 790*450*750mm |

| Package Size | 820*490*880mm |

![Floor Grinding Machine For Sale Floor Grinding Machine For Sale]() | ![Floor Grinding Machine For Sale Floor Grinding Machine For Sale]() | ![Floor Grinding Machine For Sale Floor Grinding Machine For Sale]() |

The JADE-450SH's quick-change diamond tool system enables fast transitions, minimizing downtime and maximizing productivity. It's perfect for professionals focused on efficiency and seamless workflow. | The JADE-450SH’s quick-change diamond tool system saves time, minimizes downtime, and ensures seamless transitions, maximizing efficiency. | The JADE-450SH’s dust-proof design safeguards components, ensuring durability, reliable performance, and smooth operation in tough conditions. |

![Floor Grinding Machine For Sale Floor Grinding Machine For Sale]()

| Enhanced (dual drive technology). The JADE-450SH’s quick-change diamond tool system transforms the tool replacement process, reducing downtime and saving time. This feature ensures smooth transitions between tasks, making it ideal for professionals prioritizing efficiency and steady productivity. |

Split design The segmented design enhances practicality and cost-efficiency by simplifying maintenance, reducing replacement costs, and improving performance. | ![Floor Grinding Machine For Sale Floor Grinding Machine For Sale]() |

![Floor Grinding Machine For Sale Floor Grinding Machine For Sale]() |

Always in control The upgraded control panel features an intuitive interface and quick responsiveness. Built for comfort and precision, it ensures reliable performance, even with gloves, in tough environments. |

Ergonomically designed handl The JADE-450SH, featuring a 450mm working width and six 155mm grinding discs, ensures fast and efficient performance.

| ![Floor Grinding Machine For Sale Floor Grinding Machine For Sale]() |

![Floor Grinding Machine For Sale Floor Grinding Machine For Sale]() | ![Floor Grinding Machine For Sale Floor Grinding Machine For Sale]() |

The JADE-450SH, with a 450mm working width and six 155mm grinding discs, delivers exceptional efficiency for fast, effective results. |

![Floor Grinding Machine For Sale Floor Grinding Machine For Sale]() |

The JADE-450SH’s disc arrangement allows edge grinding within 2mm of corners, ensuring precision and minimizing manual effort. |

![Diamond grinding discs Diamond grinding discs]() | ![Diamond grinding discs Diamond grinding discs]() | ![Resin abrasive discs Resin abrasive discs]() | ![Resin abrasive discs Resin abrasive discs]() |

Diamond grinding discs Fast working speed and long service life

| Resin abrasive discs With many different particle sizes, you can achieve even more surface effects. |

Exhibition

Certifications

![1724319988818564.jpg 证书800宽.jpg]() | ![1724314560514496.jpg 证书宽400高800.jpg]() |

The machine's CE certification guarantees compliance with stringent safety and environmental standards, providing a safe working environment. | ISO Quality Management System Certification |

Product packaging

FAQ

Q:Differences from other suppliers?

A:We use a seamless plastic water tank and an aluminum-cast grinder head, offering superior strength and optimal grinding pressure for exceptional performance.

Q:What should I pay attention to when using this machine?

A:a. Ensure proper use of the power cable by selecting the appropriate diameter based on the model (refer to the product specification sheet), and always guarantee effective grounding to prevent electrical leakage.

b. Avoid crushing the power cable during use, as this could damage the cable and pose an electrical shock hazard.

c. Keep the equipment and electrical outlets away from water or overly humid environments to prevent the risk of short circuits.

Q: Is the quality of your gear superior to that of other companies?

A: Yes, we make the gear our own. JS gear is skewed tooth and being heat treatment processed which guarantee stable performance and long life time. But many company don’t use such gear because this gear need high-precision process. We make the gears with CNC machine.