The JADE-450SH is a standout addition to the series, blending exceptional performance with impressive cost-effectiveness. Equipped with a powerful motor and advanced Dual Drive Technology, it provides precise control over the grinding disc and grinding head speed, making it a versatile solution for various flooring projects, including the ability to effectively grind down concrete floors. This combination of power and innovation positions the JADE-450SH as a top choice for professionals who require both high efficiency and flexibility in their work, whether for large-scale applications or intricate tasks. Its durability and ease of use ensure long-lasting, reliable performance across diverse environments.

![Grinder Machine For Concrete Grinder Machine For Concrete]()

PARAMETER

| Motor Power | 3kW |

| Rated Voltage/frequency | AC220V/50Hz/60Hz |

| Rated Current | 12.5A/11.7A |

| Inverter Power | 4kW |

| Working Width | 450mm |

| Weight | 154kg |

| Grinding Pressure Weight | 120kg |

| Transmission Method | Synchronous Belt |

| Gearbox Type | / |

| Damping Form | Rubber Damping |

| Grinding Disc Type | Round |

| Grinding Disc | 155mm |

| Number Of Grinding Wheels | 6 |

| Number Of Abrasive Discs | 2*6pcs |

| Grinding Motor Speed | 300~1800r/min |

| Travel Drive | Hand push |

| Work Efficiency (Max) | 300㎡/h |

| Power Supply Wiring | 4mm² |

| Body Dimensions | 790*450*750mm |

| Package Size | 820*490*880mm |

![Grinder Machine For Concrete Grinder Machine For Concrete]() | ![Grinder Machine For Concrete Grinder Machine For Concrete]() | ![Grinder Machine For Concrete Grinder Machine For Concrete]() |

The JADE-450SH’s quick-change diamond tool system enables faster transitions and minimizes downtime, making it ideal for efficiency-focused professionals. | The integrated timer on the JADE-450SH tracks operational hours and performance speed, providing accurate data for productivity analysis and maintenance planning. | The JADE-450SH’s dust-proof design protects components from harsh conditions, ensuring reliable performance and effortless operation in tough environments. |

![Grinder Machine For Concrete Grinder Machine For Concrete]()

| Enhanced (dual drive technology). Equipped with advanced Dual Drive Technology, the JADE-450SH offers precise control over disc speeds, allowing independent adjustments to both disc rotation and grinding head movement. This results in enhanced flexibility and efficiency, making it an essential tool for various construction applications. |

Fine grinding and worry-free edges The segmented design strikes a perfect balance between practicality and cost-efficiency, simplifying maintenance, lowering replacement costs, and boosting overall performance. | ![Grinder Machine For Concrete Grinder Machine For Concrete]() |

![Grinder Machine For Concrete Grinder Machine For Concrete]() |

Always in control The upgraded control panel in the latest model boasts an intuitive interface and quick responsiveness. Designed for operator comfort, it ensures precise control and reliable performance, even when wearing gloves, making it perfect for challenging work environments. |

Ergonomically designed handle The JADE-450SH’s adjustable handle prioritizes operator comfort, reducing fatigue during extended use. This ergonomic feature highlights the machine’s combination of high performance and user-friendly design. | ![Grinder Machine For Concrete Grinder Machine For Concrete]() |

![Grinder Machine For Concrete Grinder Machine For Concrete]() | ![Grinder Machine For Concrete Grinder Machine For Concrete]() |

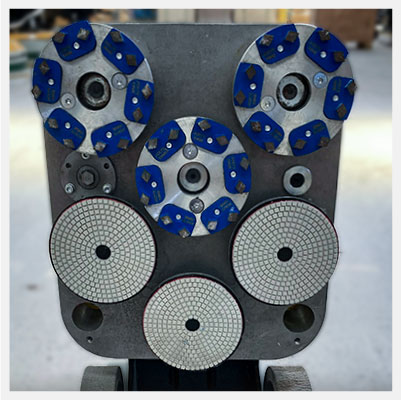

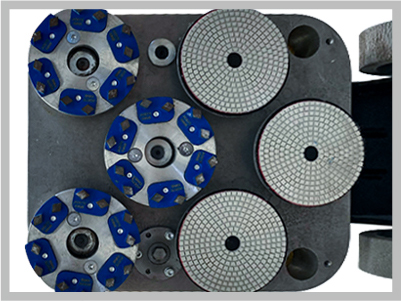

With a 450mm working width and six 155mm grinding discs, the JADE-450SH offers exceptional efficiency, ideal for large-scale projects. Its ability to grind up to 300 square meters per hour showcases its powerful performance and advanced design. |

![Grinder Machine For Concrete Grinder Machine For Concrete]() |

The JADE-450SH’s innovative disc arrangement enables edge grinding as close as 2mm to corners, ensuring precise results and reducing the need for extra manual effort. |

![Diamond grinding discs Diamond grinding discs]() | ![Diamond grinding discs Diamond grinding discs]() | ![Resin abrasive discs Resin abrasive discs]() | ![Resin abrasive discs Resin abrasive discs]() |

Diamond grinding discs Fast working speed and long service life

| Resin abrasive discs With many different particle sizes, you can achieve even more surface effects. |

Exhibition

Certifications

![1724319988818564.jpg 证书800宽.jpg]() | ![1724314560514496.jpg 证书宽400高800.jpg]() |

The machine's CE certification guarantees compliance with stringent safety and environmental standards, providing a safe working environment. | ISO Quality Management System Certification |

Product packaging

FAQ

Q:What sets you apart from other suppliers?

A:We incorporate a seamless plastic water tank and an aluminum-cast grinder head, delivering exceptional strength and boosting grinding pressure for optimized performance.

Q:Are your gears of higher quality compared to those provided by other companies?

A:Yes, we manufacture our own gears. The JS gear features a skewed tooth design and undergoes heat treatment, ensuring stable performance and a long lifespan. Many companies don’t use this type of gear due to the high-precision processing required. We produce our gears using CNC machines for maximum accuracy.

Q: Is it possible to customize your machines?

A: Yes, we can design and build machines customized to meet the specific needs of our clients.