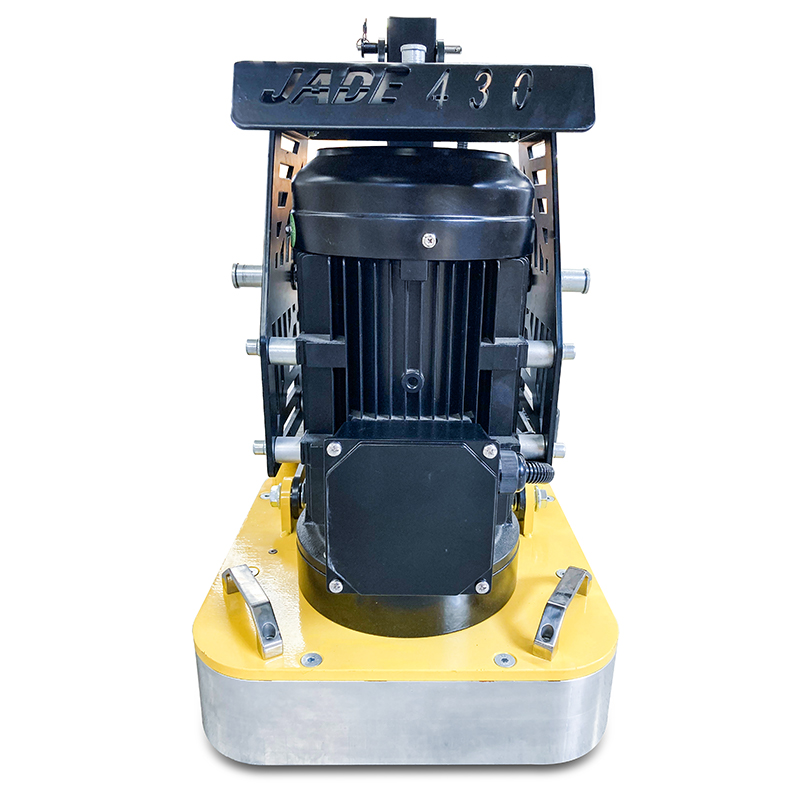

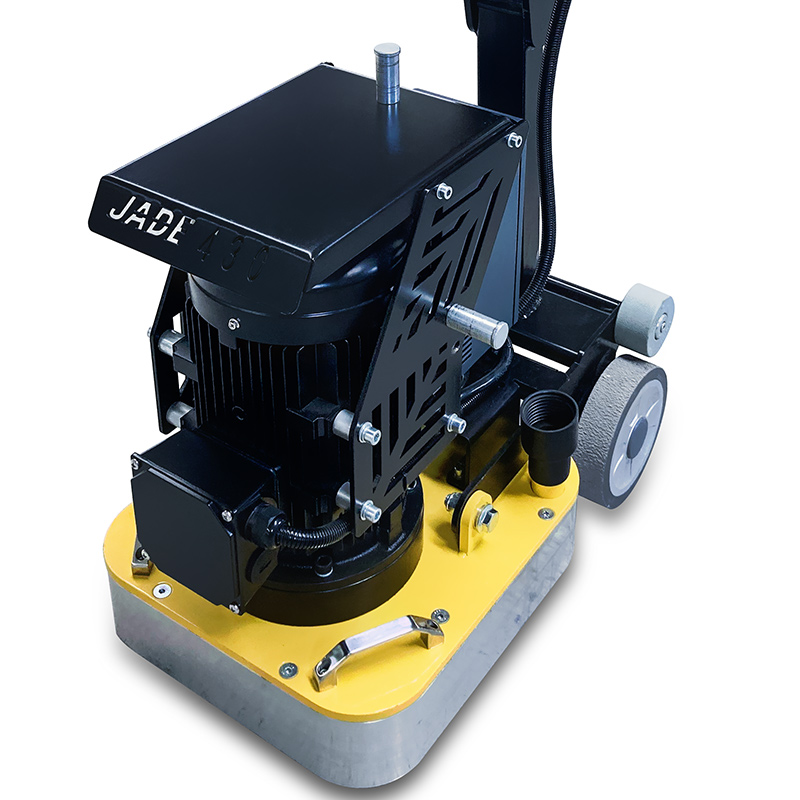

The Industrial-Grade High-Performance Floor Grinder

The JADE-430SH is a concrete floor edge grinder designed for primary grinding, milling roughening, and polishing applications on concrete, natural stone, and terrazzo surfaces. With its enhanced design, it offers an improved, efficient, and dependable solution for construction projects, effectively overcoming the inaccuracies associated with traditional grinding machinery when it comes to precise grinding of edges and corners.

![GroundLevel Concrete Grinder GroundLevel Concrete Grinder]()

PARAMETER

| Product Model | JADE-430SH |

| Motor Power | 7.5kW |

| Rated Voltage/frequency | AC220V/50Hz |

| Rated Current | 29.3A |

| Inverter Power | 7.5kW |

| -Working Width | 430mm |

| Weight | 185KG |

| Grinding Pressure Weight | 95kg |

| Transmission Method | Synchronous Belt |

| Gearbox Type | Square Gearboxes |

| Damping Form | Rubber Damping |

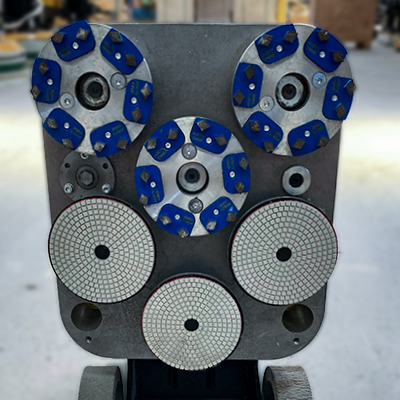

| Grinding Disc Type | Round |

| Grinding Disc | 155mm |

| Number Of Grinding Wheels | 6 |

| Number Of Abrasive Discs | 2*6pcs |

| Grinding Motor Speed | 300~1455r/min |

| Travel Drive | Hand push |

| Work Efficiency (Max) | 300㎡/h |

| Power Supply Wiring | 4mm² |

| Body Dimensions | 790*430*800mm |

![GroundLevel Concrete Grinder GroundLevel Concrete Grinder]() | ![GroundLevel Concrete Grinder GroundLevel Concrete Grinder]() | ![GroundLevel Concrete Grinder GroundLevel Concrete Grinder]() |

Hourly and tacho gauges an installed timer keeps track of the hours worked and reads the speed of the machine. | Quick changeover saves time and effort The JADE-430SH flooring machine's diamond tool change system is fast and reliable, greatly enhancing construction efficiency. | Low maintenance, smooth operation Completely sealed against dust, ensuring long-lasting durability and worry-free operation in a variety of harsh environments |

![GroundLevel Concrete Grinder GroundLevel Concrete Grinder]()

| Enhanced (dual drive technology). JADE's cutting-edge Dual Drive Technology gives the machine superior disc speed control. This proprietary technology not only allows you to independently adjust the speed and direction of rotation of the discs, but also to precisely control the speed and direction of the grinding head, resulting in more flexible and efficient construction operations. |

Protected electronic equipment The sealed design of the JADE-430SH floor machine ensures that dust and moisture cannot intrude, thus effectively protecting the internal components of the machine from potential damage and ensuring long-term stable operation.

| ![GroundLevel Concrete Grinder GroundLevel Concrete Grinder]() |

![GroundLevel Concrete Grinder GroundLevel Concrete Grinder]() |

Always in control The new generation of control panels has been carefully redesigned to provide not only more intuitive operating feedback, but also to take into account the needs of the operator when wearing gloves, ensuring precise control even in harsh working conditions.

|

Ergonomically designed handle JADE-430SH flooring machine is equipped with an adjustable handle, this ergonomic design makes the operation more comfortable, adapts to the physical conditions of different operators, and reduces fatigue brought about by long-time operation. | ![GroundLevel Concrete Grinder GroundLevel Concrete Grinder]() |

![GroundLevel Concrete Grinder GroundLevel Concrete Grinder]() | ![GroundLevel Concrete Grinder GroundLevel Concrete Grinder]() |

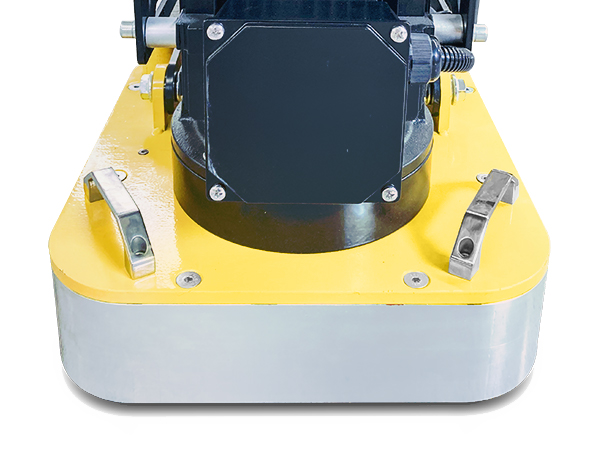

Adjustable grinding pressure

Optional weights enhance professional floor grinder performance while simplifying tilting operations.

|

![GroundLevel Concrete Grinder GroundLevel Concrete Grinder]() |

Three preset levels of the counterweight allow the user to easily adjust the grinding pressure. |

![1725496958638494.jpg 金属磨片2.jpg]() | ![1725496953630257.jpg 金属磨片1.jpg]() | ![1725438818932734.jpg 树脂磨片1.jpg]() | ![1725438822971569.jpg 树脂磨片2.jpg]() |

Diamond grinding discs Fast working speed and long service life

| Resin abrasive discs With many different particle sizes, you can achieve even more surface effects. |

Exhibition

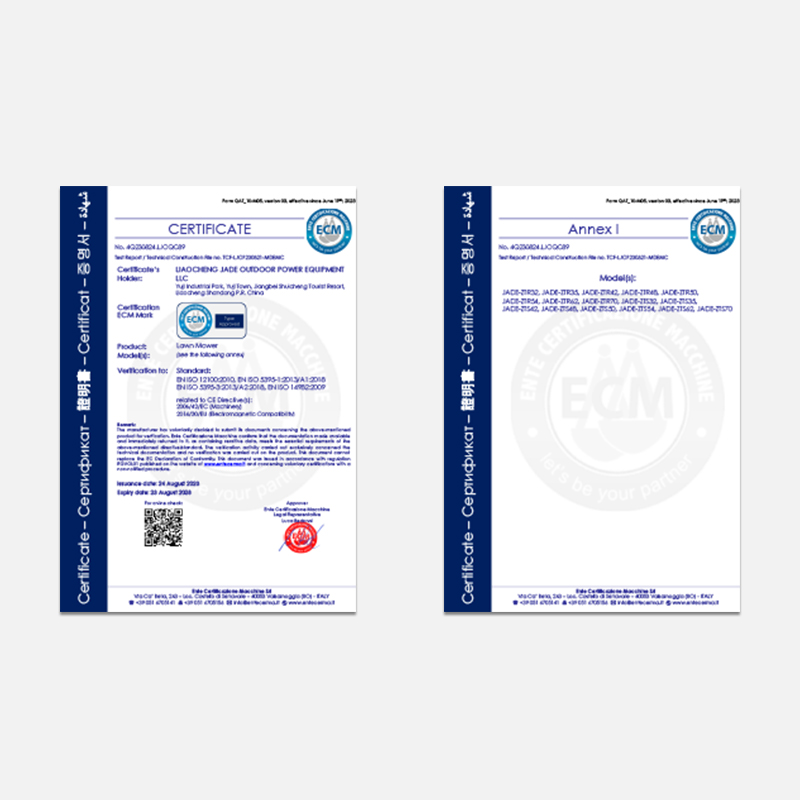

Certifications

![1724319988818564.jpg 证书800宽.jpg]() | ![1724314560514496.jpg 证书宽400高800.jpg]() |

The machine's CE certification guarantees compliance with stringent safety and environmental standards, providing a safe working environment. | ISO Quality Management System Certification |

Product packaging

FAQ

Can l have a coloured concrete floor?

A: Yes. Using the latest surfacing materials to apply decorative coatings, you can have a concretefloor in almost any colour you want. The decorative coatings we apply to the surface also makethe concrete stronger and more durable than ordinary concrete.

Q: Can you polish damaged concrete?

A: As long as the structure of the concrete slab is sound, almost any concrete floor is suitable forgrinding or polishing. Old concrete usually needs surface preparation before grinding andsome patching is generally fine.

Q: Does concrete grinding leave dust?

A: We vacuum as we grind and polish concrete using specialised vacuum cleaners for concretedust. This eliminates the majority of dust, but due to the nature of the work, there can still besmall amounts of residual dust.