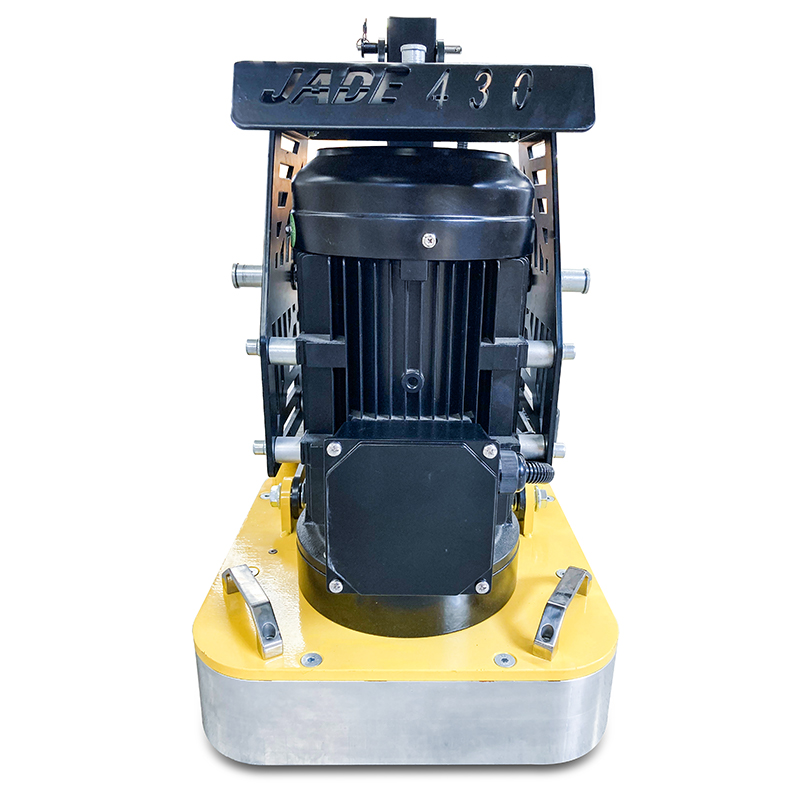

The Industrial-Grade High-Performance Edge Grinder

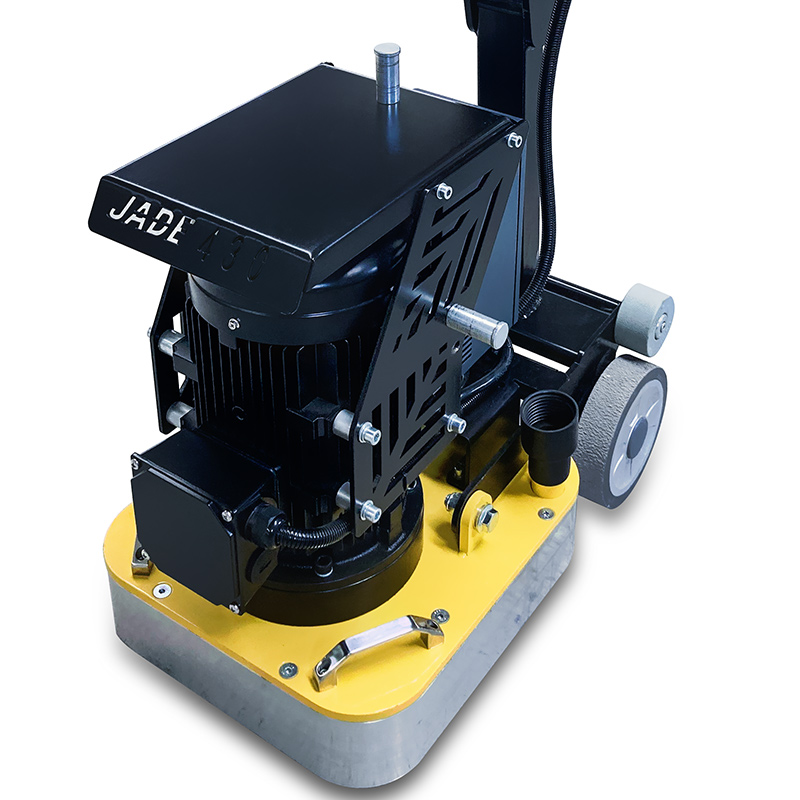

The JADE-430SH is a high-performance, industrial-grade floor grinder designed for exceptional results in primary grinding, milling, and polishing on surfaces such as concrete, natural stone, and terrazzo. With its innovative design, this machine offers enhanced efficiency and dependability, making it a standout choice for construction projects. It effectively tackles the common challenges of grinding edges and corners, providing a more precise and uniform finish compared to traditional grinding method

![1725434471578181.jpg 视频2.jpg]()

PARAMETER

| Product Model | JADE-430SH |

| Motor Power | 7.5kW |

| Rated Voltage/frequency | AC220V/50Hz |

| Rated Current | 29.3A |

| Inverter Power | 7.5kW |

| -Working Width | 430mm |

| Weight | 185KG |

| Grinding Pressure Weight | 95kg |

| Transmission Method | Synchronous Belt |

| Gearbox Type | Square Gearboxes |

| Damping Form | Rubber Damping |

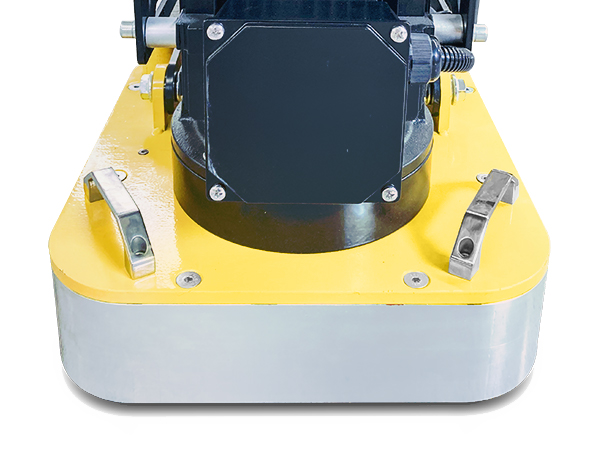

| Grinding Disc Type | Round |

| Grinding Disc | 155mm |

| Number Of Grinding Wheels | 6 |

| Number Of Abrasive Discs | 2*6pcs |

| Grinding Motor Speed | 300~1455r/min |

| Travel Drive | Hand push |

| Work Efficiency (Max) | 300㎡/h |

| Power Supply Wiring | 4mm² |

| Body Dimensions | 790*430*800mm |

![1724895552539152.jpg 计时器.jpg]() | ![1724895598392781.jpg 快速换磨盘.jpg]() | ![1724898465995155.jpg 密封-1.jpg]() |

The JADE-430SH includes an hour meter for work hour tracking and a tachometer for speed control, enhancing operational efficiency and maintenance. | The JADE-430SH flooring machine offers a fast and secure diamond tool change mechanism, optimizing productivity on construction sites. | The JADE-430SH flooring machine is fully dust-sealed for reliable operation in tough conditions. |

![1725237986789050.jpg 800×800.jpg]()

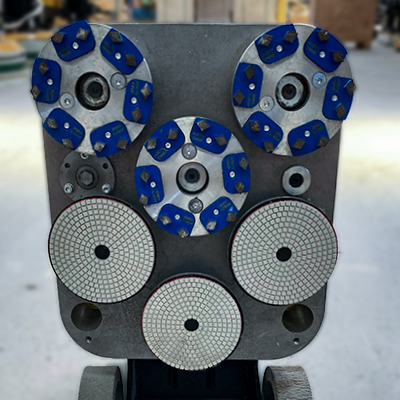

| Enhanced (dual drive technology). JADE's unique Dual Drive Technology equips the machine with sophisticated disc speed control, allowing independent adjustment of disc rotation and grinding head movement, thus improving the flexibility and efficiency of construction operations. |

Protected electronic equipment The JADE-430SH floor machine is designed with a sturdy sealed structure that keeps out dust and moisture, protecting its internal components and ensuring enduring, dependable operation.

| ![1725331371246632.jpg 密封壳.jpg]() |

![1724897818577112.jpg 操控面板-2.jpg]() |

Always in control The JADE-430SH floor machine features a revamped control panel that is more user-friendly and operable, even with gloves on, providing precise control in tough working conditions.

|

Ergonomically designed handle TThe JADE-430SH flooring machine comes with an adjustable handle that enhances comfort and ergonomics, catering to different user heights and reducing operator fatigue during prolonged use. | ![1724986539253028.jpg 手柄.jpg]() |

![1724986749723962.jpg 800×800.jpg]() | ![1724899046932702.jpg 配重.jpg]() |

Adjustable grinding pressure

Optional weights on the JADE-430SH flooring machine improve performance and ease of tilting.

|

![1724987416233816.jpg 配重3.jpg]() |

The JADE-430SH flooring machine includes a counterweight system with three preset settings, enabling quick and convenient tuning of the machine's grinding pressure. |

![1725496900199452.jpg 金属磨片2.jpg]() | ![1725496904497449.jpg 金属磨片1.jpg]() | ![1725438905508580.jpg 树脂磨片1.jpg]() | ![1725438908132238.jpg 树脂磨片2.jpg]() |

Diamond grinding discs Fast working speed and long service life

| Resin abrasive discs With many different particle sizes, you can achieve even more surface effects. |

Exhibition

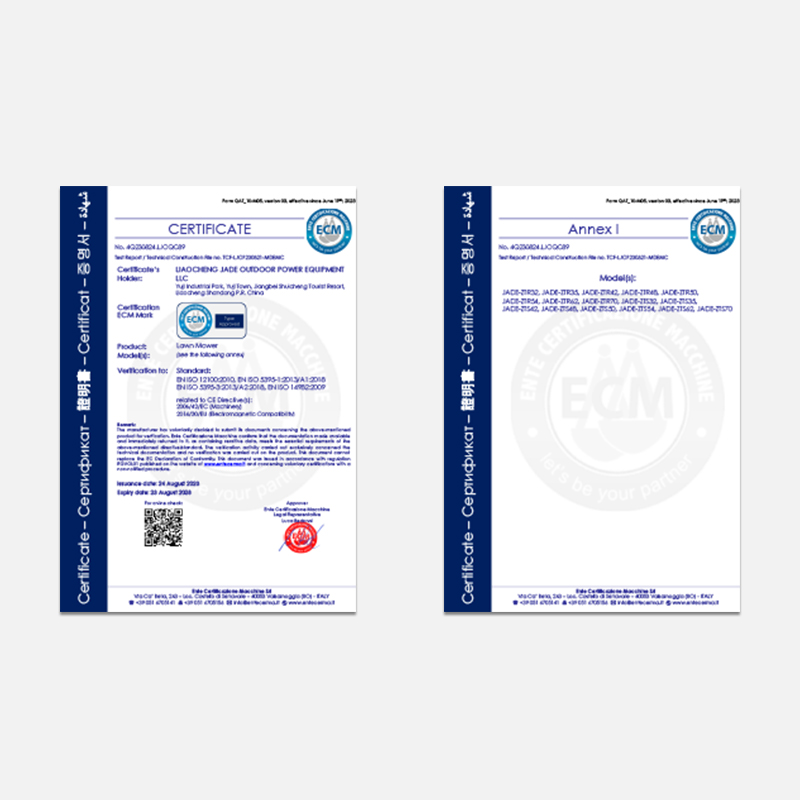

Certifications

![1724319988818564.jpg 证书800宽.jpg]() | ![1724314560514496.jpg 证书宽400高800.jpg]() |

The machine's CE certification guarantees compliance with stringent safety and environmental standards, providing a safe working environment. | ISO Quality Management System Certification |

Product packaging

FAQ

Q: What are the main application scenarios for the JADE-430SH Floor Grinder?

A: The JADE-430SH is suitable for preliminary grinding, milling, roughening and polishing operations on concrete, natural stone and terrazzo surfaces.

Q: What are the maintenance intervals for this machine?

A: Routine inspection is recommended every 50 hours of operation and full maintenance is recommended every 200 hours of operation. Specific maintenance intervals may vary depending on the environment and frequency of use.

Q: What documents are needed to export to other countries?

A. Commercial invoices, packing lists, bills of lading and certificates of origin are usually required. Specific documents may vary depending on the destination country.

Q. How do I deal with duties and taxes in the importing country?

A: We provide the necessary export documentation and assist our customers in understanding the tariff policies of the destination country. Specific duties and taxes are handled by the importer according to local regulations.