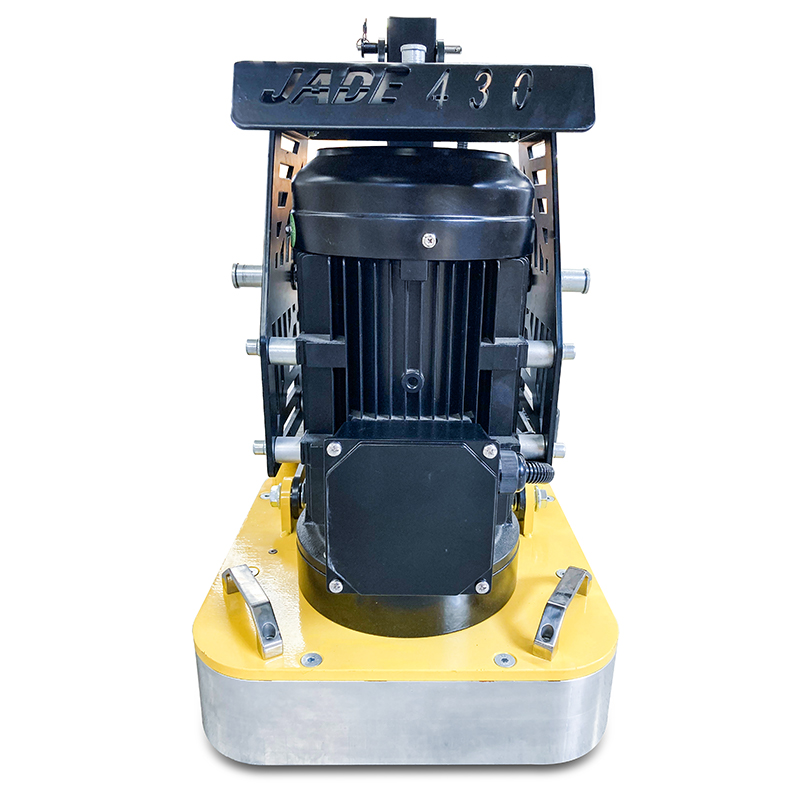

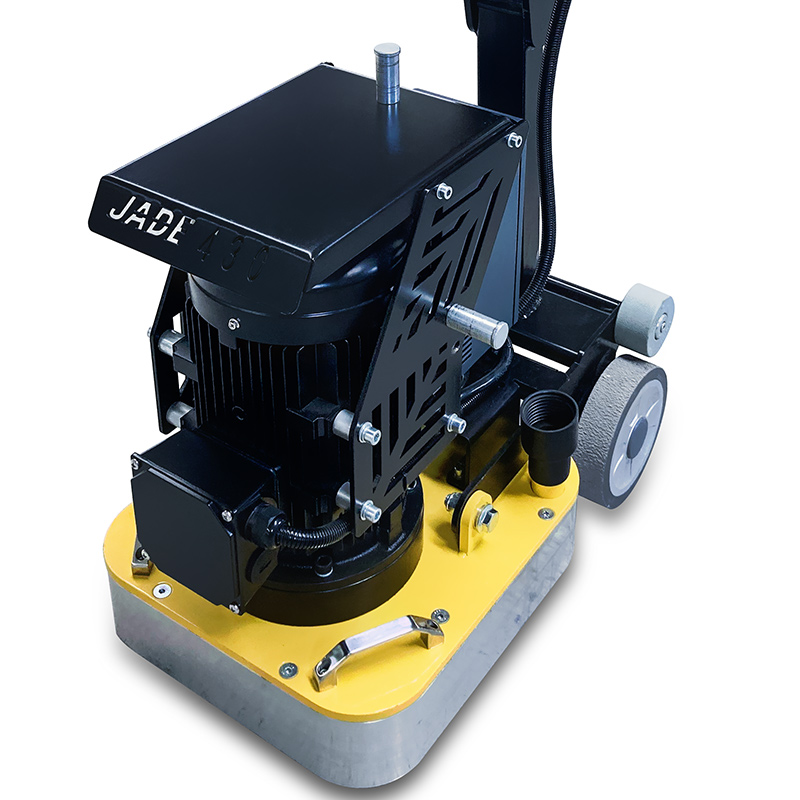

The JADE-430SH is indeed a versatile and powerful tool tailored for professional floor grinding applications. Its ability to handle primary grinding, milling, roughening, and polishing makes it suitable for a wide range of surfaces, including concrete, natural stone, and terrazzo. The focus on precise edge and corner grinding is particularly valuable for areas where traditional equipment might struggle, such as tight corners or along walls. With its innovative design, the JADE-430SH not only boosts efficiency but also provides durability, making it a reliable choice for demanding construction projects like warehouse floor preparation and concrete surface finishing.

![Rotary Concrete Grinder Rotary Concrete Grinder]()

PARAMETER

| Product Model | JADE-430SH |

| Motor Power | 7.5kW |

| Rated Voltage/frequency | AC220V/50Hz |

| Rated Current | 29.3A |

| Inverter Power | 7.5kW |

| -Working Width | 430mm |

| Weight | 185KG |

| Grinding Pressure Weight | 95kg |

| Transmission Method | Synchronous Belt |

| Gearbox Type | Square Gearboxes |

| Damping Form | Rubber Damping |

| Grinding Disc Type | Round |

| Grinding Disc | 155mm |

| Number Of Grinding Wheels | 6 |

| Number Of Abrasive Discs | 2*6pcs |

| Grinding Motor Speed | 300~1455r/min |

| Travel Drive | Hand push |

| Work Efficiency (Max) | 300㎡/h |

| Power Supply Wiring | 4mm² |

| Body Dimensions | 790*430*800mm |

![Rotary Concrete Grinder Rotary Concrete Grinder]() | ![Rotary Concrete Grinder Rotary Concrete Grinder]() | ![Rotary Concrete Grinder Rotary Concrete Grinder]() |

The JADE-430SH's hourly gauge tracks total operating hours, helping schedule timely maintenance to extend the machine's lifespan and prevent downtime. | The JADE-430SH's quick-change tool system allows fast replacements, minimizing downtime and increasing productivity. | The JADE-430SH's sealed design ensures low maintenance, durability, and reliable performance, even in tough conditions. |

![Rotary Concrete Grinder Rotary Concrete Grinder]()

| Enhanced (dual drive technology).

JADE's Dual Drive Technology offers exceptional precision, enabling independent control of disc and grinding head speed and direction. This boosts versatility and efficiency, ideal for flat concrete grinding and more. |

Protected electronic equipment The JADE-430SH small concrete grinder features a sealed design that shields internal components from dust and moisture, ensuring lasting stability and reliable operation.

| ![Rotary Concrete Grinder Rotary Concrete Grinder]() |

![Rotary Concrete Grinder Rotary Concrete Grinder]() |

Always in control The new control panel generation provides intuitive feedback, ensuring precise control even for operators wearing gloves in tough work environments.

|

Ergonomically designed handle The joystick is adjustable and ergonomic, making your work easier. | ![Rotary Concrete Grinder Rotary Concrete Grinder]() |

![Rotary Concrete Grinder Rotary Concrete Grinder]() | ![Rotary Concrete Grinder Rotary Concrete Grinder]() |

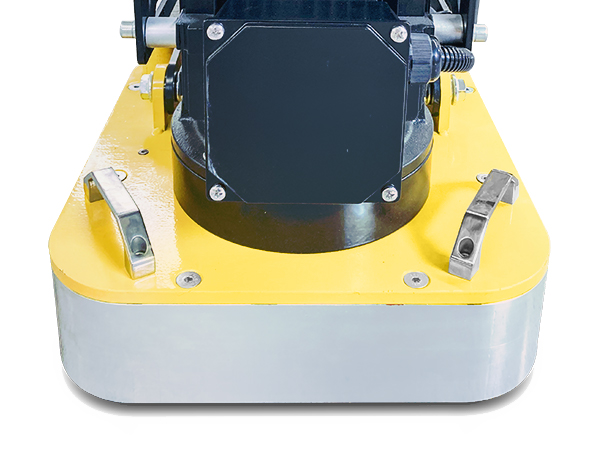

Adjustable grinding pressure Optional weights enhance the performance of professional floor grinders, making tilting easier and increasing overall efficiency. |

![Rotary Concrete Grinder Rotary Concrete Grinder]() |

The three preset counterweight levels enable users to adjust the grinding pressure easily, tailoring it to specific needs. |

![1725496958638494.jpg 金属磨片2.jpg]() | ![1725496953630257.jpg 金属磨片1.jpg]() | ![1725438818932734.jpg 树脂磨片1.jpg]() | ![1725438822971569.jpg 树脂磨片2.jpg]() |

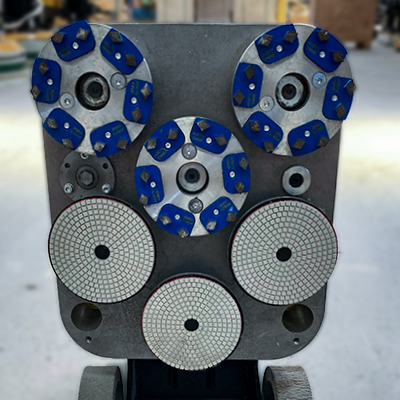

Diamond grinding discs Fast working speed and long service life

| Resin abrasive discs With many different particle sizes, you can achieve even more surface effects. |

Exhibition

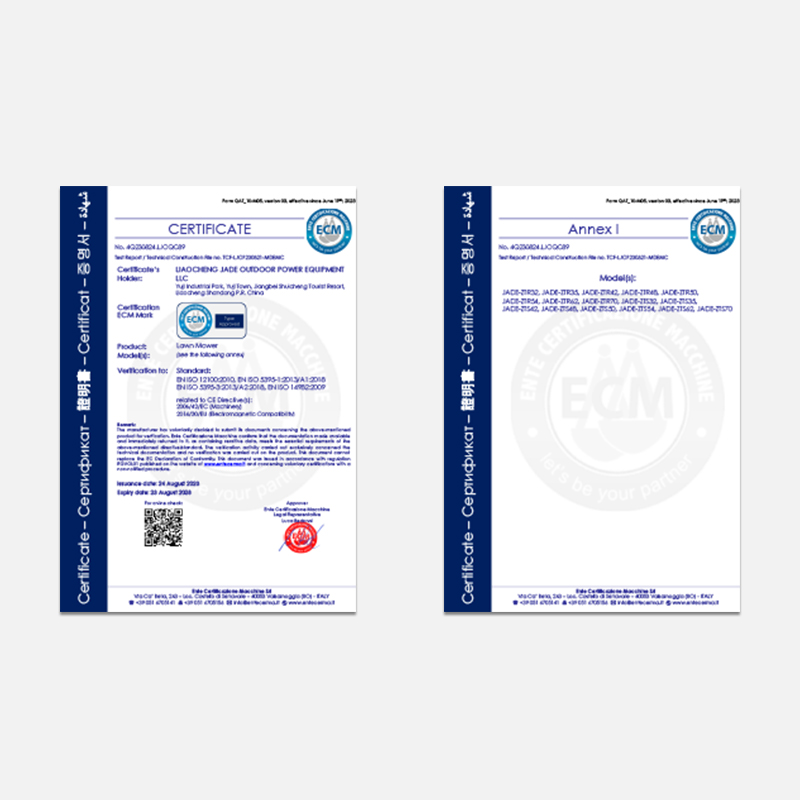

Certifications

![1724319988818564.jpg 证书800宽.jpg]() | ![1724314560514496.jpg 证书宽400高800.jpg]() |

The machine's CE certification guarantees compliance with stringent safety and environmental standards, providing a safe working environment. | ISO Quality Management System Certification |

Product packaging

FAQ

Q: an your machines be customized?

A: Yes, we can design and manufacture machines based on the client's specific requirements.

Q: Is the quality of your gears superior to that of other companies?

A: Yes, we manufacture our own gears. Our JS gears feature skewed teeth and undergo heat treatment, ensuring stable performance and a long lifespan. Many companies don't use this type of gear due to the high-precision processing required, but we produce them with CNC machines to guarantee quality.

Q: Do you have any design advantages compared to other suppliers?

A: Yes, we do. For instance, we use a seamless plastic water tank and an aluminum casting mold grinder head, which is stronger and enhances grinding pressure.