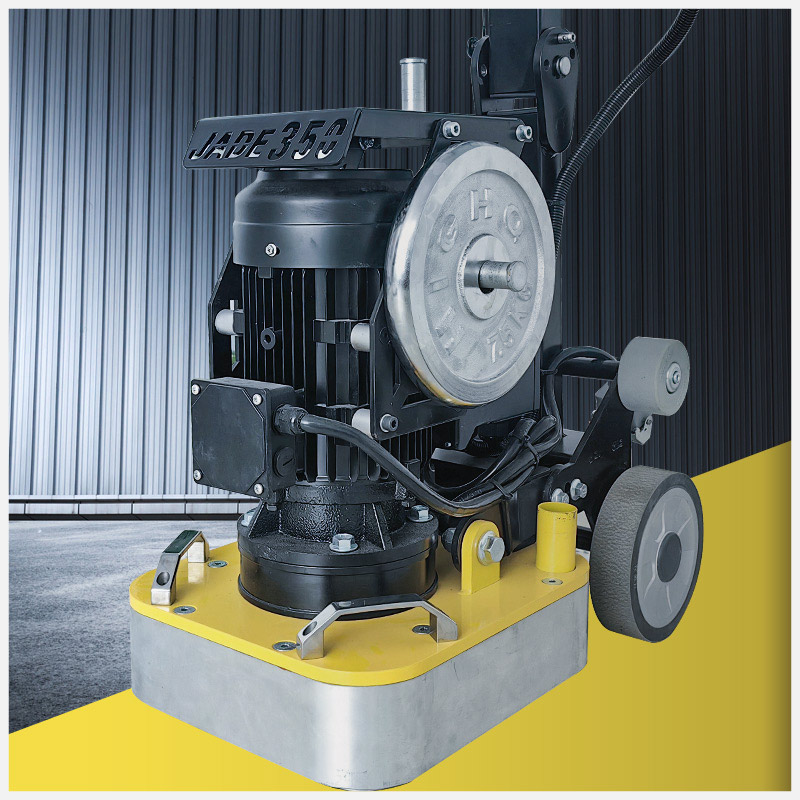

Discover the JADE-350SH Floor Grinder: A Game-Changer in Industrial Flooring Solutions.

Discover the pinnacle of industrial flooring technology with the JADE-350SH Floor Grinder, a marvel of modern engineering designed to revolutionize the benchmarks of efficiency and precision in floor finishing. This innovative tool embodies the essence of what a contemporary construction team seeks to elevate their projects to the pinnacle of durability and visual appeal.

Unsurpassed Performance:

At the core of the JADE-350SH lies a powerful 3kW motor, paired with a robust 4kW inverter, ensuring relentless power and dependability on any construction site.

Effortless Efficiency:

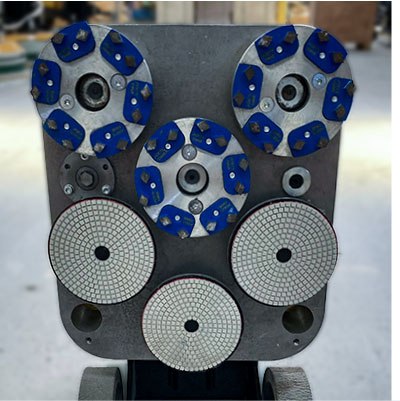

With a generous 350mm working width and equipped with six 130mm precision round grinding discs, this powerhouse effortlessly tackles tasks, achieving a remarkable maximum work efficiency of 300㎡/h, redefining productivity standards.

Durable Construction:

Weighing in at a sturdy 98kg, supported by a 46KG grinding pressure weight and enhanced rubber damping, the JADE-350SH is engineered to endure, delivering unwavering performance even under the most strenuous conditions.

Innovative Features:

Voltage/Frequency: The JADE-350SH's versatility is evident with its ability to operate on AC220V/50Hz/60Hz, positioning it as a global solution for any flooring challenge.

Rated Current: Maintaining a consistent 12.3A/11.7A current draw, this grinder guarantees reliable performance irrespective of the workload.

Disc Configuration: The six round grinding discs exemplify the machine's uniform grinding capabilities, ensuring a perfect finish every time.

Abrasives Included: A comprehensive kit of 26 abrasives ensures readiness for any flooring scenario.

Variable Speed: The grinding motor's adjustable speed from 300 to 1430 revolutions per minute allows for tailored grinding to achieve the best possible results.

The JADE-350SH Floor Grinder is the ultimate partner for a broad spectrum of commercial and industrial flooring applications, including concrete, epoxy, and wear-resistant surfaces. It is ideally suited for construction sites, manufacturing facilities, storage areas, and parking lots, where only superior floor preparation will suffice. Embrace the JADE-350SH Floor Grinder and take your flooring projects to unprecedented levels of excellence. Experience the transformative impact of innovation and power in your construction projects.

![Concrete & Edge Grinder Concrete & Edge Grinder]()

PARAMETER

| Product Model | JADE-350SH |

| Motor Power | 3kW |

| Rated Voltage/frequency | AC220V/50Hz/60Hz |

| Rated Current | 12.3A/11.7A |

| Inverter Power | 4kW |

| Working Width | 350mm |

| Weight | 98kg |

| Grinding Pressure Weight | 46KG |

| Transmission Method | Synchronous Belt |

| Gearbox Type | Square Gearboxes |

| Damping Form | Rubber Damping |

| Grinding Disc Type | Round |

| Grinding Disc | 130mm |

| Number Of Grinding Wheels | 6 |

| Number Of Abrasive Discs | 2*6pcs |

| Grinding Motor Speed | 300-1430r/min |

| Travel Drive | Hand push |

| Work Efficiency (Max) | 300㎡/h |

| Power Supply Wiring | 4mm² |

| Body Dimensions | 710*350*630mm |

| Package Size | 855*460*740mm |

![Floor Grinder Polisher Floor Grinder Polisher]() | ![Floor Grinder Polisher Floor Grinder Polisher]() | ![Floor Grinder Polisher Floor Grinder Polisher]() |

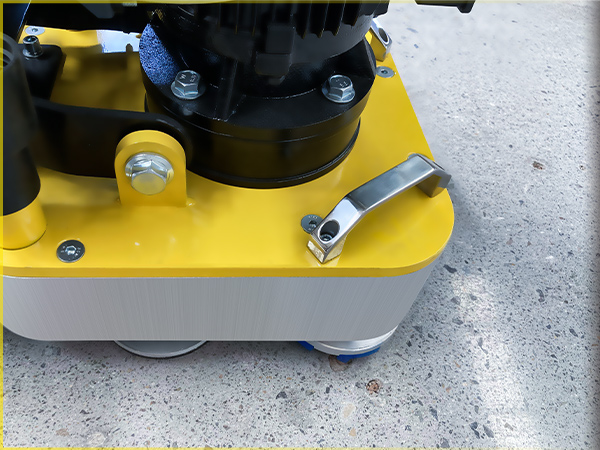

Quick transitions for time and effort savings.

Effortless and swift trading of diamond cutting instruments | Hourly and odometer indicators.

It is practical to record the time spent on work tasks and measure the efficiency of the equipment in use. | Easy maintenance for a hassle-free experience. An enhanced dual-motor drive mechanism equipped with extensive dust protection. |

![Floor Grinder Polisher Floor Grinder Polisher]()

| Enhanced (dual drive technology). JADE's exclusive Dual Drive Technology enables the equipment to achieve superior rotational velocities for the grinding disc. This innovative feature offers the ability to separately control the speed and orientation of the disc, as well as the velocity and positioning of the grinding head. |

Protected electronic equipment The components are protected from damage by effectively preventing dust and water from entering.

| ![Floor Grinder Polisher Floor Grinder Polisher]() |

![Floor Grinder Polisher Floor Grinder Polisher]() |

No Dead End Grinding Enhance the design of the grinding disc so that it can closely align with walls, whether they are straight or curved. This ensures comprehensive grinding coverage, eradicating areas that are difficult to reach, and efficiently addresses the challenges of grinding in corners or near structural supports.

|

can be connected to a vacuum cleaner By incorporating a vacuum cleaner attachment, the work environment is kept clear of dust contamination.

| ![Floor Grinder Polisher Floor Grinder Polisher]() |

![1725933024303191.jpg 画板 12.jpg]() | ![1725933571341307.jpg 2222.jpg]() |

Supplementary accessories such as extra weights are essential for professional-grade grinders, facilitating the easy tilting of the machine as required. |

![1725933575218766.jpg 111.jpg]() |

This feature is enabled by the provision of three preset configurations that enable users to accurately regulate the grinding pressure. |

![1725934160152019.jpg 画板-15_01.jpg]() | ![1725934165248816.jpg 画板-15_02.jpg]() | ![1725934169485872.jpg 画板-15_03.jpg]() | ![1725934170359242.jpg 画板-15_04.jpg]() |

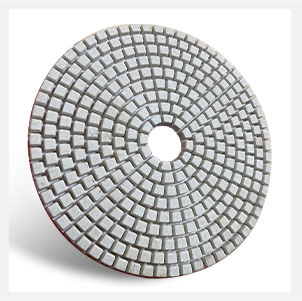

Diamond grinding discs Fast working speed and long service life

| Resin abrasive discs With many different particle sizes, you can achieve even more surface effects. |

Exhibition

Certifications

![1724319988818564.jpg 证书800宽.jpg]() | ![1724314560514496.jpg 证书宽400高800.jpg]() |

The machine's CE certification guarantees compliance with stringent safety and environmental standards, providing a safe working environment. | ISO Quality Management System Certification |

Product packaging

FAQ

Q: What are the standout features of the JADE 350SH floor grinder?A: The JADE 350SH floor grinder is distinguished by its robust 3kW motor and 4kW inverter, featuring a 350mm operational width. It is fitted with six 130mm grinding discs, ensuring high-efficiency in construction tasks. Weighing in at 98kg, it boasts a grinding pressure of 46KG, enhanced with rubber shock absorption and a bevel gear box for improved stability and durability.

Q: What are the detailed technical specifications of the JADE 350SH?A: The JADE 350SH's technical specs include a rated voltage/frequency of AC220V/50Hz/60Hz, a rated current of 12.3A/11.7A, circular grinding discs, a total of 26 discs, and a variable grinding motor speed from 300 to 1430 revolutions per minute (r/min).

Q: In which construction settings is the JADE 350SH typically used?A: The JADE 350SH is tailored for various commercial and industrial flooring applications, including concrete, epoxy, and wear-resistant floors. It is frequently utilized in construction sites, industrial facilities, storage facilities, and parking garages.

Q: What are the recommended daily maintenance and care practices for the JADE 350SH?A: Regular inspections of key components such as the drive belt, gear box, and shock absorption system are crucial. It's essential to clean the machine's exterior and grinding discs to remove dust and debris, and to apply lubricant to the gear box and transmission system as required to ensure peak performance.