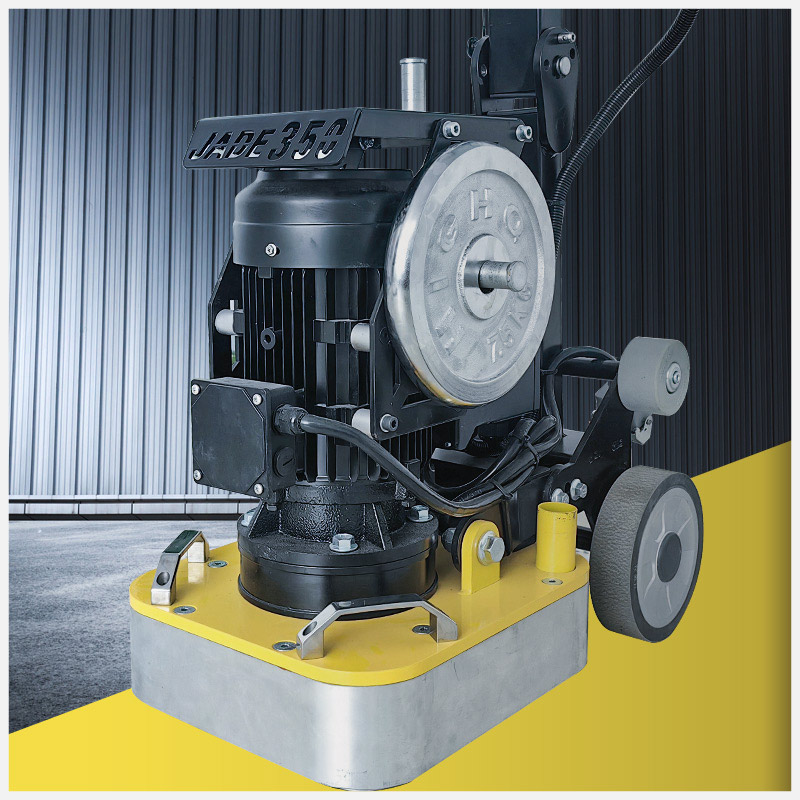

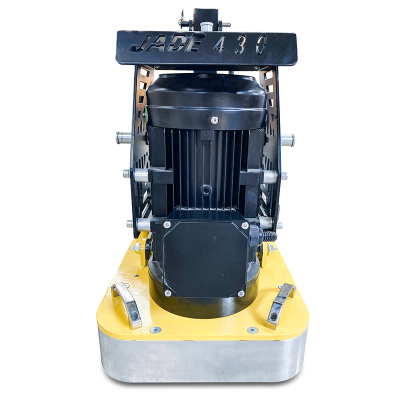

JADE-350SH Floor Grinder - A Revolutionary Tool for Industrial Floor Construction.

In the field of industrial floor construction, efficiency and quality are key indicators for measuring the success of a project. The JADE-350SH floor grinder, as an innovator in the industry, offers an unparalleled construction experience for the construction team with its excellent performance and innovative technology. Here is a detailed introduction to the JADE-350SH floor grinder, allowing you to appreciate how it has become the ideal choice for floor construction.

Core Performance Highlights:

Powerful Performance: The JADE-350SH floor grinder is equipped with a 3kW motor and a 4kW inverter, ensuring high efficiency and stability during construction.

Efficient Operation: With a 350mm working width and six 130mm round grinding discs, the JADE-350SH can achieve an impressive work rate of up to 300㎡/h at maximum efficiency.

Durability and Strength: Weighing 98kg and featuring a grinding pressure of 46KG, coupled with rubber damping and square gearboxes, the machine ensures stability and durability during long periods of high-intensity operation.

Technical Specifications:

Rated Voltage/Frequency: AC220V/50Hz/60Hz, adaptable to the power standards of different countries and regions.

Rated Current: 12.3A/11.7A, ensuring stable operation of the equipment under various loads.

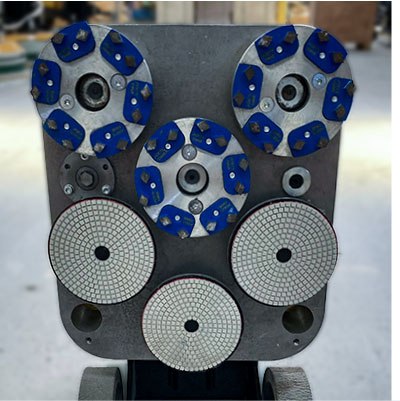

Grinding Disc Type: Round grinding discs, with a configuration of six discs, providing uniform grinding effects.

Number of Abrasive Discs: 26 pieces/26pcs, meeting various construction needs.

Grinding Motor Speed: 300-1430r/min, adjustable according to construction requirements to achieve the best grinding effect.

The JADE-350SH floor grinder is suitable for various commercial and industrial floor constructions, including but not limited to concrete floors, epoxy floors, and wear-resistant floors. It is an ideal choice for construction sites, factory workshops, warehouses, and parking lots.

![Concrete & Edge Grinder Concrete & Edge Grinder]()

PARAMETER

| Product Model | JADE-350SH |

| Motor Power | 3kW |

| Rated Voltage/frequency | AC220V/50Hz/60Hz |

| Rated Current | 12.3A/11.7A |

| Inverter Power | 4kW |

| Working Width | 350mm |

| Weight | 98kg |

| Grinding Pressure Weight | 46KG |

| Transmission Method | Synchronous Belt |

| Gearbox Type | Square Gearboxes |

| Damping Form | Rubber Damping |

| Grinding Disc Type | Round |

| Grinding Disc | 130mm |

| Number Of Grinding Wheels | 6 |

| Number Of Abrasive Discs | 2*6pcs |

| Grinding Motor Speed | 300-1430r/min |

| Travel Drive | Hand push |

| Work Efficiency (Max) | 300㎡/h |

| Power Supply Wiring | 4mm² |

| Body Dimensions | 710*350*630mm |

| Package Size | 855*460*740mm |

![1725932951253249.jpg 00000_01.jpg]() | ![1725932957759500.jpg 00000_02.jpg]() | ![1725932961566440.jpg 00000_03.jpg]() |

Fast changeover for time and effort savings.

Effortless and swift diamond tool swap. | Hourly and tacho gauges

It is feasible to document the hours dedicated to work and ascertain the operational velocity of the machinery. | Low maintenance, smooth operation Enhanced dual-drive gearbox with full dust protection. |

![1726037427124599.jpg 画板 1.jpg]()

| Enhanced (dual drive technology). JADE's exclusive Dual Drive Technology enables the machine to achieve greater rotational velocities for the grinding disc. This innovation permits independent control over the disc's spin rate and direction, as well as the grinding head's movement speed and orientation. |

Protected electronic equipment Components are safeguarded from damage as dust and water are effectively blocked from entering.

| ![1726037436757477.jpg 画板 2.jpg]() |

![1726037443669371.jpg 画板 8.jpg]() |

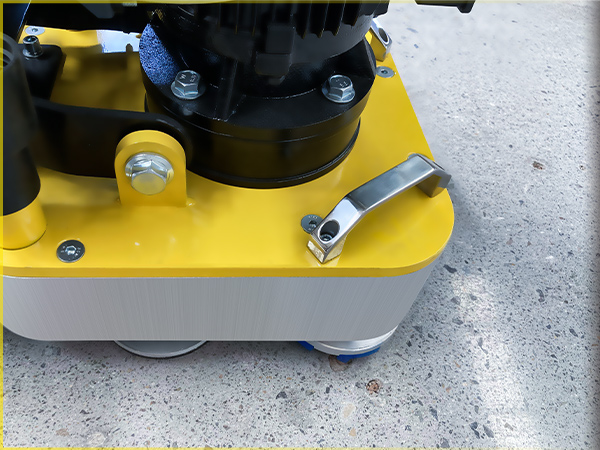

No Dead End Grinding Enhance the design of the grinding disc to enable it to closely approach walls, whether they are right-angled or curved. This ensures comprehensive grinding with no unreachable areas and effectively addresses the challenges of grinding in corners or near columns.

|

can be connected to a vacuum cleaner With the attachment of a vacuum cleaner, the working environment will not be exposed to dust. | ![1725933365759531.jpg 4.jpg]() |

![1725933024303191.jpg 画板 12.jpg]() | ![1725933571341307.jpg 2222.jpg]() |

Accessories such as optional weights are essential for professional grinders, facilitating the tilting of the machine with ease. |

![1725933575218766.jpg 111.jpg]() |

This capability is due to the presence of three pre-set positions that enable the user to fine-tune the grinding pressure. |

![1725934160152019.jpg 画板-15_01.jpg]() | ![1725934165248816.jpg 画板-15_02.jpg]() | ![1725934169485872.jpg 画板-15_03.jpg]() | ![1725934170359242.jpg 画板-15_04.jpg]() |

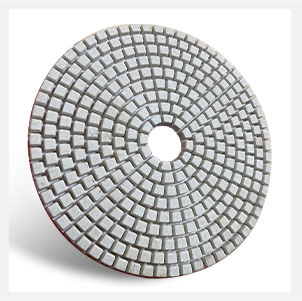

Diamond grinding discs Fast working speed and long service life

| Resin abrasive discs With many different particle sizes, you can achieve even more surface effects. |

Exhibition

Certifications

![1724319988818564.jpg 证书800宽.jpg]() | ![1724314560514496.jpg 证书宽400高800.jpg]() |

The machine's CE certification guarantees compliance with stringent safety and environmental standards, providing a safe working environment. | ISO Quality Management System Certification |

Product packaging

FAQ

Q: What are the main features of the JADE 350SH floor grinder?A: The JADE 350SH floor grinder offers robust power with its 3kW motor and 4kW inverter, a working width of 350mm, and 6 grinding discs of 130mm, ensuring efficient construction. It also features a weight of 98kg and a grinding pressure of 46KG, as well as rubber shock absorption and a bevel gear box, ensuring the machine's stability and durability.

Q: What are the technical specifications of the JADE 350SH?A: The technical specifications include a rated voltage/frequency of AC220V/50Hz/60Hz, a rated current of 12.3A/11.7A, circular grinding disc type, 26 grinding discs/26pcs, and a grinding motor speed range of 300-1430r/min.

Q: What construction environments is the JADE 350SH suitable for?A: It is suitable for a variety of commercial and industrial floor construction environments, including concrete floors, epoxy floors, wear-resistant floors, and more, such as construction sites, factory workshops, warehouses, and parking lots.

Q: How to perform daily maintenance and care for the JADE 350SH?A: It is recommended to regularly check the wear condition of key components such as the drive belt, gear box, and shock absorption system, promptly clean the dust and residue on the machine surface and grinding discs, and regularly lubricate the gear box and transmission system.