Product Overview:The 260 Model Chamfered Corner Floor Grinder is a high-efficiency equipment designed specifically for grinding complex structures and chamfered corners of concrete and terrazzo surfaces. Its compact size and powerful performance make it an ideal choice for building renovation, ground maintenance, and precision finishing projects.

Technical Specifications:

Motor Power: Equipped with a high-efficiency motor to ensure sufficient power for handling hard surface materials.

Grinding Width: A working width of 260mm, suitable for precise grinding of chamfered structures.

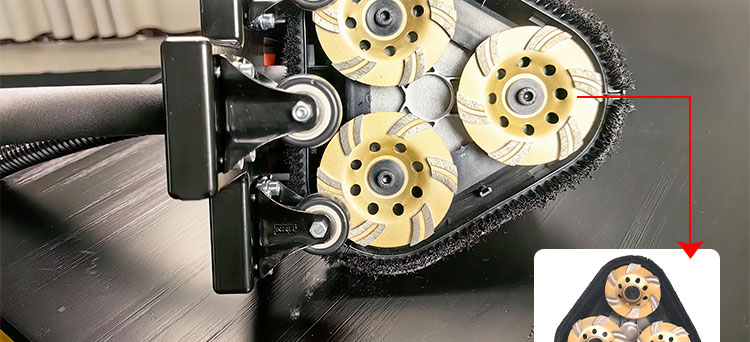

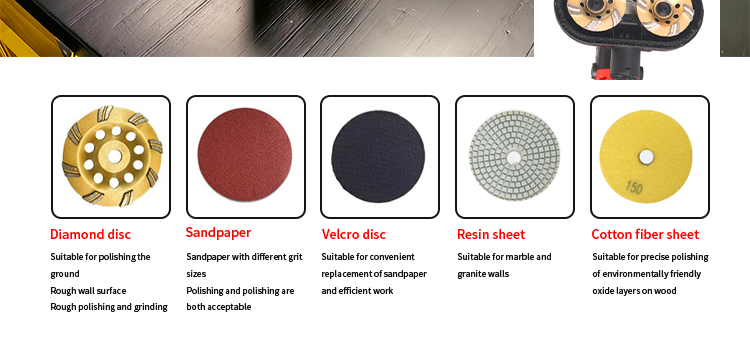

Grinding Disc Size: Compatible with various standard sizes of grinding discs, with specialized grinding pads available for chamfered corner grinding.

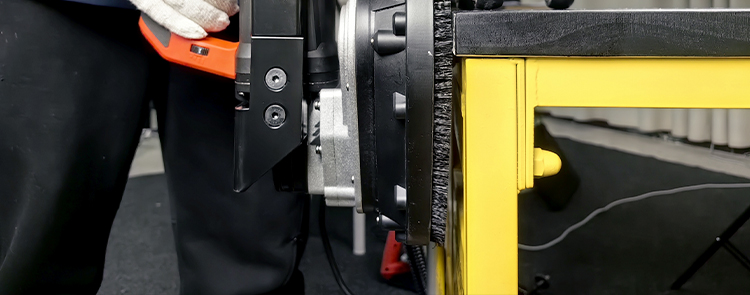

Drive Type: Hand-push design provides good controllability and precise grinding positioning.

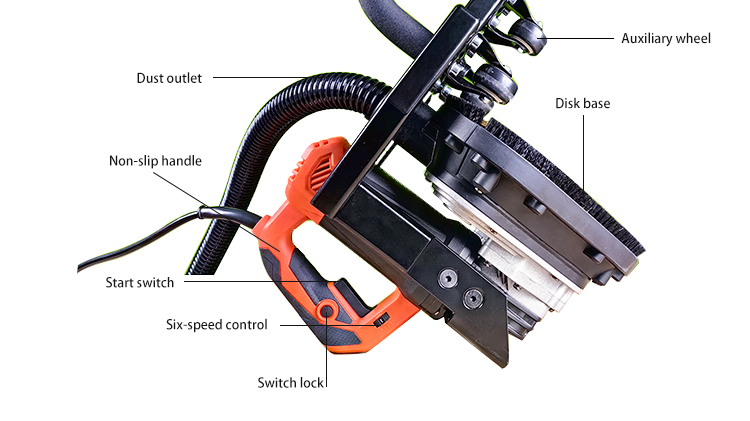

Grinding Speed: Adjustable grinding speed to accommodate different hardness of ground materials and fine grinding requirements.

Weight and Dimensions: Designed to be lightweight and easy to operate in narrow spaces and challenging chamfered areas.

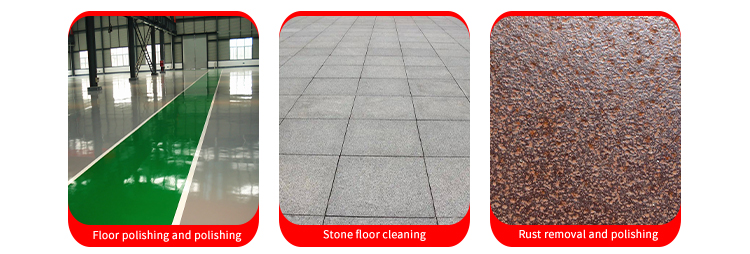

Application Scenarios:The 260 Model Chamfered Corner Floor Grinder is particularly suitable for occasions that require precise grinding, such as the edges of concrete structures, corners of terrazzo floors, and chamfered areas of other hard surfaces. It excels in building renovation, public facility maintenance, commercial space transformation, and historical building restoration projects, ensuring smooth transitions and consistent grinding quality in chamfered areas.

Product Advantages:

Specialized Chamfered Corner Processing: Designed for precise grinding of chamfered corners and complex structures, ensuring neat and aesthetically pleasing ground processing.

Convenient Operation: Hand-push operation is simple and easy to control, enabling efficient grinding even in hard-to-reach areas.

Strong Adaptability: Adjustable grinding speed and a variety of grinding pad options allow it to handle various ground materials and grinding tasks.

Durable Construction: High-quality materials and manufacturing processes ensure the long-term durability and reliability of the equipment.

Low Maintenance Costs: The design considers the convenience of maintenance, reducing downtime and operating costs.

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()

![Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind Hot Sale 220v 3 Heads Concrete Handheld Edge Grinder For Stone Terrazzo Tiles Grind]()