Planetary Concrete Sander: The Ultimate Solution for Efficient Concrete Grinding

Planetary Concrete Sander: The Ultimate Solution for Efficient Concrete Grinding

Introduction

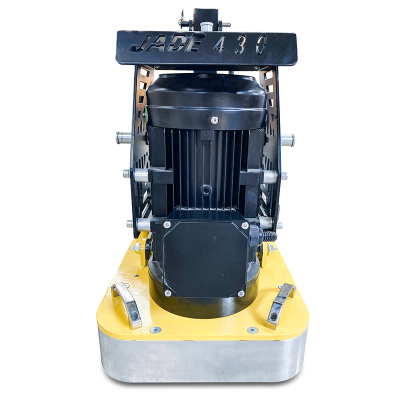

In construction renovation, industrial flooring, or home improvement, achieving a smooth and polished concrete surface is crucial. An efficient and durable grinding tool can significantly enhance project efficiency and quality. The Planetary Concrete Sander is a game-changer in this field. This article delves into its core advantages, applications, and purchasing tips to help you find the ideal surface treatment tool.

1. Why Choose a Planetary Concrete Sander?

Planetary Design for Uniform Grinding

The Planetary Concrete Sander features a unique "planetary motion" mechanism, where the grinding disc rotates while spinning on its axis. This ensures even pressure distribution, avoiding "swirl marks" or "deep scratches" often caused by traditional single-axis grinders. It is particularly suitable for fine processing of large concrete, stone, or epoxy floors.High Efficiency with Low Noise

Equipped with a vibration reduction system and low-noise motor, it reduces operator fatigue during prolonged use and meets industrial environmental standards.Versatile Applications

Whether it's rough old concrete renovation, garage floor polishing, or epoxy resin coating preparation for commercial spaces, the planetary sander can handle it all. It supports quick replacement of grinding discs with different grits.Extended Equipment Lifespan

High-quality models feature industrial-grade gearboxes and cooling designs, minimizing overheating and wear, making them ideal for heavy-duty projects.

2. Applications: Where is a Planetary Concrete Sander Needed?

Construction Sites: Quickly process newly poured concrete surfaces to enhance coating adhesion.

Warehouse/Factory Renovation: Remove oil stains and cracks from old floors, creating smooth and durable industrial surfaces.

Home Improvement: DIY polishing for basement or garage floors, improving aesthetics and dust resistance.

Commercial Spaces: Epoxy or polished concrete floor (PCC) construction for malls, hospitals, and other venues.

3. How to Choose the Right Planetary Concrete Sander?

Power and Speed

Select motor power based on project requirements (e.g., 10HP or higher for heavy-duty tasks) and ensure adjustable speed for different surface hardness levels.Disc Compatibility

Ensure the machine supports various consumables like diamond discs and resin pads to meet needs from coarse grinding to fine polishing.Portability and Automation

Models with dust collection ports can connect to vacuum systems, maintaining a clean workspace. Electric lifting functions enhance operational convenience.Brand and After-Sales Service

Choose reputable brands offering warranties and technical support to avoid delays due to part shortages.

4. Usage and Maintenance Tips

Safety First: Wear goggles, dust masks, and ensure the surface is free of loose debris.

Regular Maintenance: Clean motor vents, check disc wear, and replace damaged parts promptly.

Storage Conditions: Avoid damp or extreme temperatures to extend equipment life.

5. Why Choose Us?

As a professional construction equipment supplier, we offer:

✅ Full Range of Planetary Concrete Sanders: From light-duty to industrial-grade models to suit different budgets and needs.

✅ Genuine Consumables: Original discs and accessories ensure optimal performance.

✅ Technical Guidance and After-Sales Support: Free operation training and lifetime maintenance consultation.

Call to Action (CTA)

Explore Our Planetary Concrete Sander Series Now and enjoy limited-time discounts and free technical manuals!

Click the link :https://www.jadeequipments.com

Or contact customer service: fila@jadeequipments.com