The definitive method for streamlined and successful garden maintenance.

The Tiercel ZTS-TZ series marks the cutting edge of lawn care technology, crafted to satisfy the needs of modern Homeowner Stand On Mower users.

These mowers are designed for high efficiency and durability, positioning them as the premier choice for homeowners seeking the Best Stand On Mower.

Powered by a robust engine, these mowers deliver outstanding performance on diverse terrains, earning them the distinction of being the Best Stand On Mower For Steep Hills.

![Best Stander Mower For Hills Best Stander Mower For Hills]()

PARAMETER

| Model Number | Tiercel ZTS-TZ 24C32 | Tiercel ZTS-TZ 24C36 | Tiercel ZTS-TZ 24C42 | Tiercel ZTS-TZ 24C50 |

| Engine | 23HP V-Twin | 23HP V-Twin | 25HP V-Twin | 25HP V-Twin |

| Deck Type | Fabricated | Fabricated | Fabricated | Fabricated |

| Displacement | 764CC | 764CC | 764CC | 764CC |

| Transmission | Hydro Gear EZT-2200 | Hydro Gear EZT-2200 | Hydro Gear EZT-2200 | Hydro Gear EZT-2200 |

| Cutting Width | 810mm | 910mm | 1050mm | 1250mm |

| Cutting Height Range | 38-114mm | 38-114mm | 38-114mm | 38-114mm |

| Blade Engagement | lectromagnetic Clutch | Electromagnetic Clutch | Electromagnetic Clutch | Electromagnetic Clutch |

| Cutter Belt Type | Premium B-section | Premium B-section | Premium B-section | Premium B-section |

| Start | Electric start | Electric start | Electric start | Electric start |

| Drive mode | zero turn | zero turn | zero turn | zero turn |

| Forward speed | 7.7mph(12.4kph) | 7.7mph(12.4kph) | 7.7mph(12.4kph) | 7.7mph (12.4kph) |

| Reverse Speed | (5.5kph) | 3.4mph(5.5kph) | 3.4mph(5.5kph) | 3.4mph (5.5kph) |

| Tires-Front | 13x5.0-6 | 13x5.0-6 | 13x5.0-6 | 13x5.0-6, |

| Tires-Rear | 18x9.5.0-8 | 18x9.5.0-8 | 18x9 | 18x9.5.0-8 |

| Hour Meter | Standard | Standard | Standard | Standard |

| Fuel capacity | 10L | 10L | 10L | 20L |

| Number of blades | Two pieces | Two pieces | Three pieces | Three pieces |

| LED Head Light | Standard | Standard | Standard | Standard |

| Weight Overall | 280kg | 292kg | 310kg | 320KG |

| Pack Size L*W*H | 1660x1006*1300mm | 1600*1100*1290mm | 1600×1250×1300mm | 1570×1400×1300mm |

| Container Load 40HQ | 36/pcs | 39/pcs | 39/pcs | 30/pcs |

PARAMETER

![Best Hill Stander Mower Best Hill Stander Mower]() | ![Best Hill Stander Mower Best Hill Stander Mower]() | ![Best Hill Stander Mower Best Hill Stander Mower]() |

Utilizing the Hydro Gear EZT-2200 hydraulic pump drive system guarantees a seamless and potent torque transfer. | Lower belt tension and cooler temps mean fewer breakdowns, better performance, and less maintenance. | The blade-engagement system, powered by an electromagnetic clutch and electric start, streamlines operation. |

![Best Hill Stander Mower Best Hill Stander Mower]()

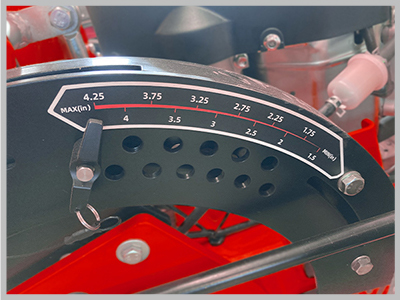

| The mower's cutting height, adjustable between 38mm to 114mm, offers flexibility for different grass species and conditions. |

The mower allows for cutting height adjustments from 38mm to 114mm, accommodating various grass types and environmental needs. | ![Best Hill Stander Mower Best Hill Stander Mower]() |

![Best Hill Stander Mower Best Hill Stander Mower]() | Fueled by either a 25HP dual-cylinder or a 23HP V-Twin engine, the mower ensures lawn maintenance is carried out with exceptional efficiency. |

The mower comes with separate controls for forward and reverse movements, supported by two stabilizer bars, and an ergonomic control setup to reduce operator fatigue on long shifts. | ![Best Hill Stander Mower Best Hill Stander Mower]() |

Exhibition

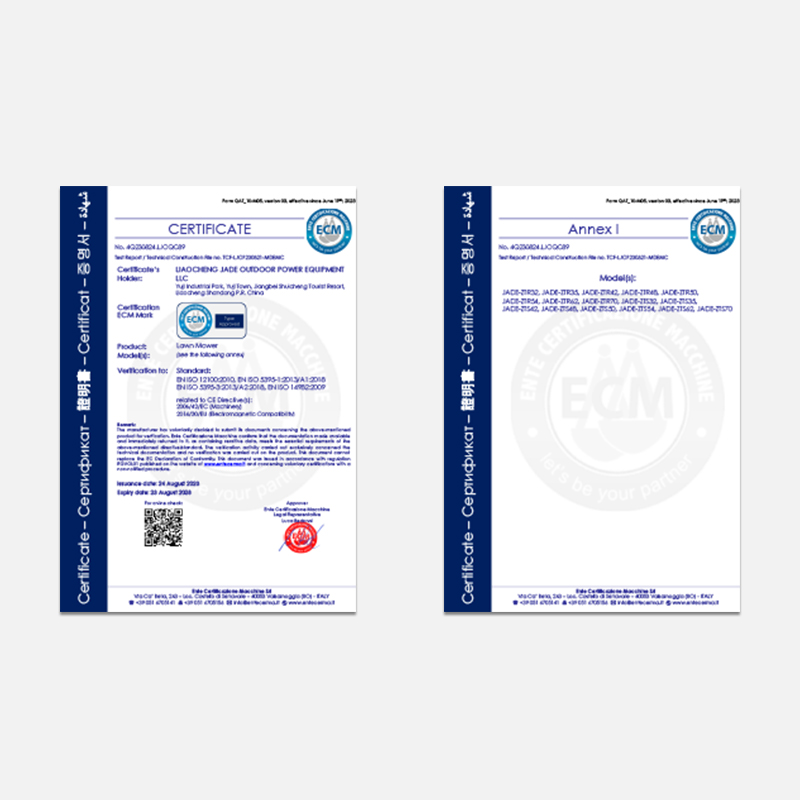

Certifications

![1724319988818564.jpg 证书800宽.jpg]() | ![1724314560514496.jpg 证书宽400高800.jpg]() |

The machine's CE certification guarantees compliance with stringent safety and environmental standards, providing a safe working environment. | ISO Quality Management System Certification |

Product packaging

FAQ

Q: What distinguishes your Professional Vertical Mowers from others?A: Our mowers are distinguished by their powerful 25-hp engine suitable for diverse landscapes, a hydraulic drive system for fluid control, and zero-turn capability for enhanced maneuverability. They offer cutting widths ranging from 810mm to 1250mm to accommodate different lawn sizes, and they all come with an electric start for convenience. Their decks are designed for durability and longevity.

Q: How do you adjust the cutting height on these mowers?A: These mowers are equipped with an electromagnetic clutch that allows for straightforward and accurate cutting height adjustments, guaranteeing uniform lawn cuts and optimal lawn health.

Q: What maintenance is essential to maintain peak performance of the mowers?A: Routine maintenance involves checking and changing the engine oil, cleaning the air filter, and examining the hydraulic system. After every 50 hours of use, it's important to inspect belts, blades, and other moving components for signs of wear.